Loving potatoes implies caring for nature. We place great importance on caring for nature and is proud to express its green philosophy via the ‘Green Factory’ label.

One of the most important steps was building our own power station. It is fed by a fermentation unit that produces biogas from waste water that’s rich in starch. The waste products do not have to be transported; they are converted into green energy (electricity and heat) on site.

This way, our production runs 100% on green energy. That process results in an interesting by-product: a fertile digestate Myfert that is used to fertilise the potato fi elds. This completes the green circle.

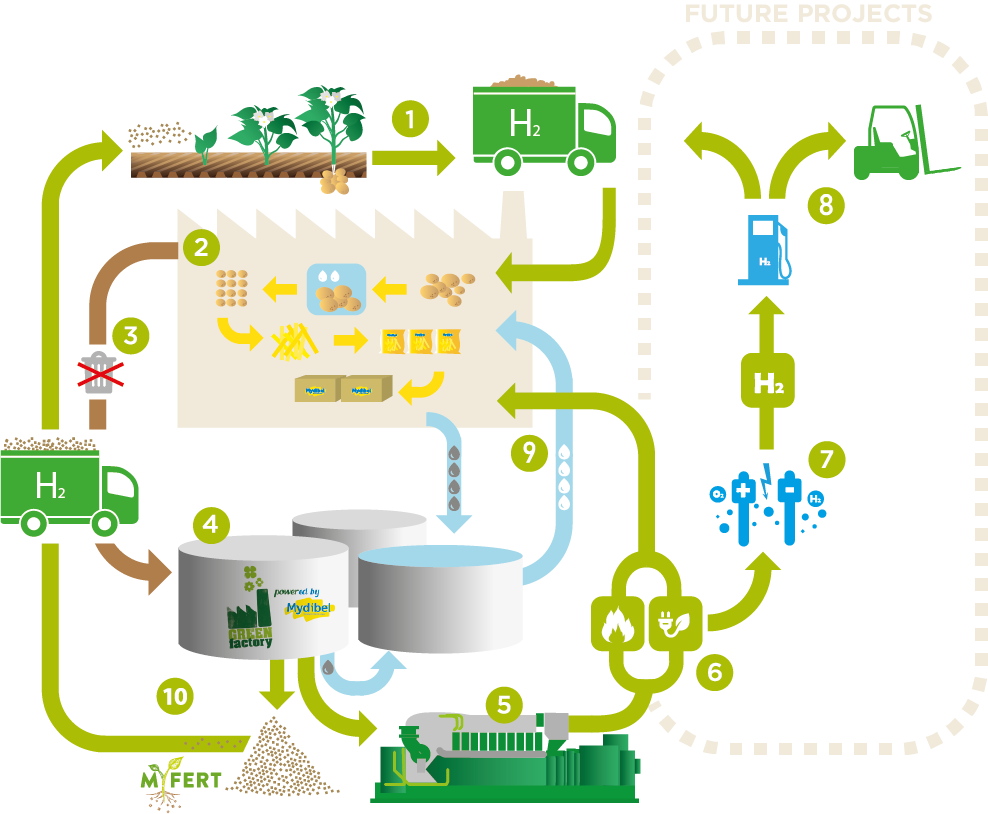

The Green Factory cycle

- The fully grown potatoes are harvested and delivered to the Mydibel factory.

- The potatoes are washed and sorted, to be processed into potato fries or other potato products.

- The bypass streams of production are not removed as waste, but processed on our own Green Factory site (reduction of 1.341.375kg of CO2 emissions / 5.110 less lorries on the road).

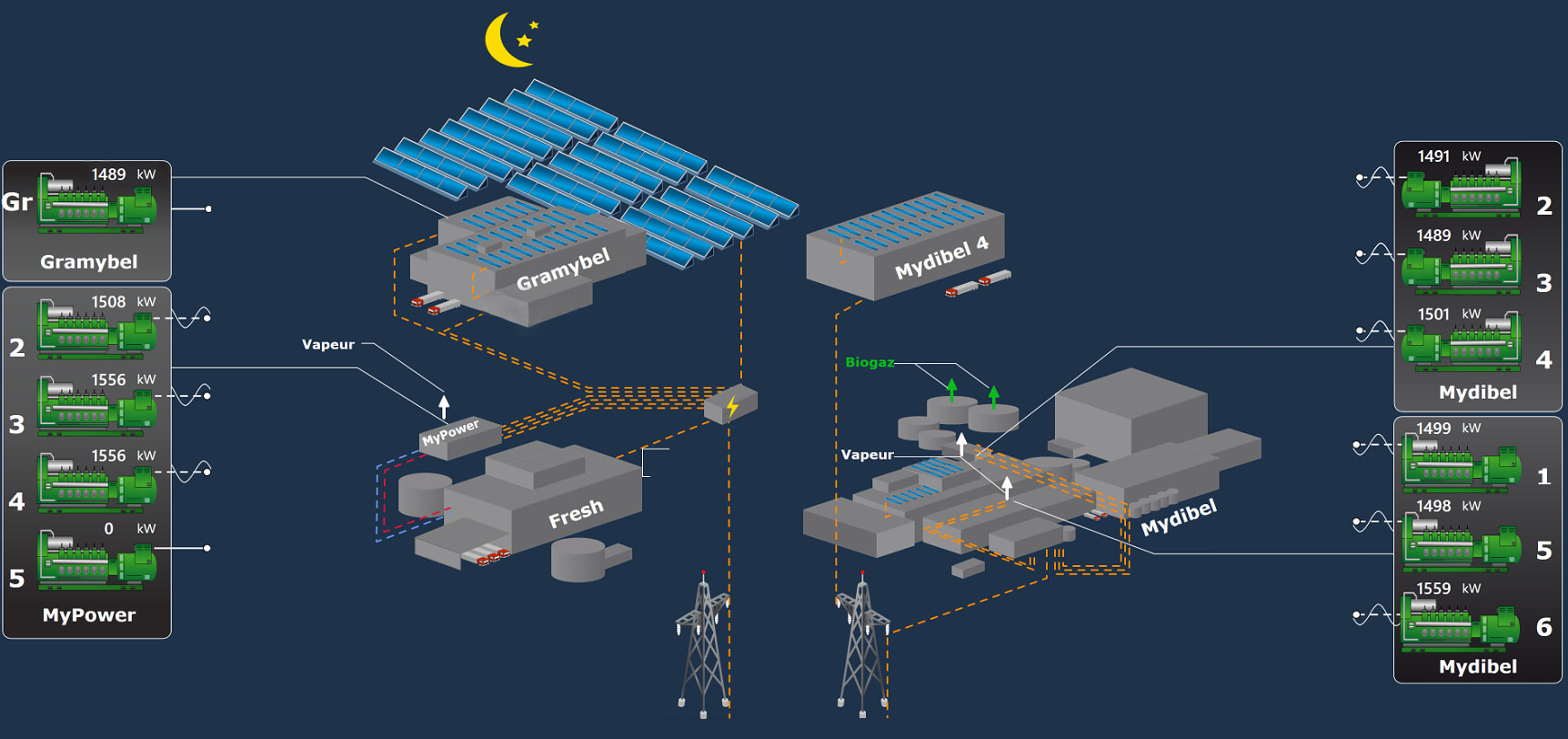

- The fermentation of the starchy waste creates biogas. The Green Factory site consists of 2 digesters and 11 biogas engines, as well as a water purification system.

- The biogas engines turn the biogas into green energy (electricity + steam + hot water).

- Mydibel generates 90% of its electricity needs, the remaining 10% is green electricity purchased from the grid. The sites of Gramybel, Mydibel Fresh and Mypower produces 120% of their electricity needs.

- The surplus electricity produced by the site will be converted into hydrogen by means of an electrolyser. This will increase the efficiency of the engines by 4% and avoid losing biogas.

- Hydrogen will be used to decarbonise mobility by renewing our fleet of trucks with dual fuel and fuel cell trucks. Several partners will follow Mydibel in this project, including the Dufour group, which will replace the garbage trucks in Mouscron with new hydrogen-powered trucks.

- The waste water from production and the potato washing system is purified on the Green Factory site, and then reused in the manufacturing process. 20% of the water used is recycled water.

- The residues of the bio-fermentation process (Myfert digestate) are rich in phosphate, nitrogen and potassium, and form the perfect fertiliser for potato fi elds or other crops.

Sustainibility report

Electricity production

Thank to our power station, our plants are fully running on green energy.

RSE Objectives

Mydibel is involved in several RSE objectives: