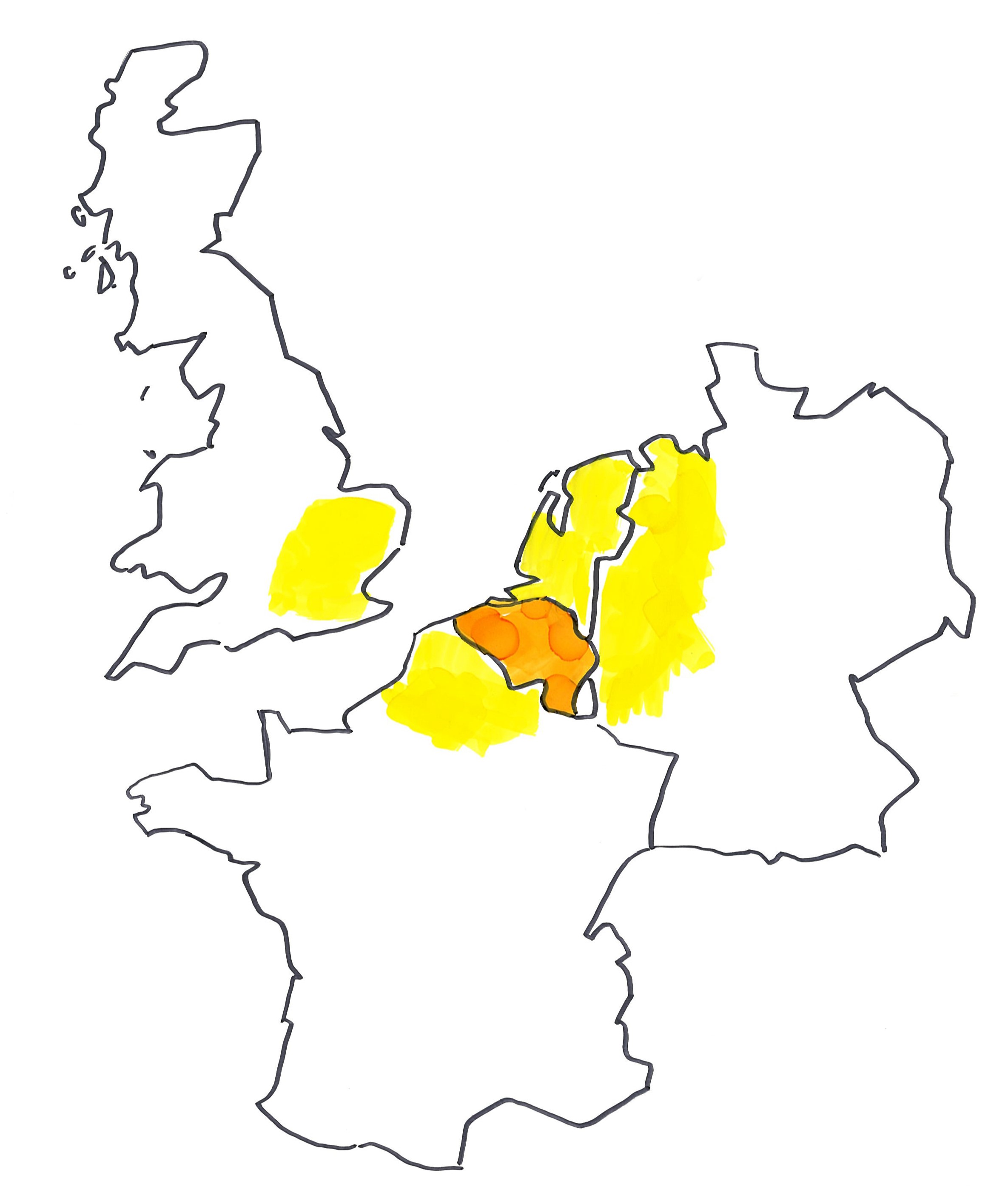

The potato belt

What is the potato belt?

The European potato belt is one of the most important potato regions for potato products in the world. Belgium, the home of Mydibel, has everything that’s needed to deliver top-class fries:

- Optimal climate (humidity, sun intensity, temperature…) and soil conditions.

- The rich potato tradition of our farmers guarantees experience and expertise.

- Professional, specialised cultivation with high yield per hectare.

- Many potato varieties with choice of early, half-late and late varieties.

- Constant innovation in every link of the potato chain.

- Lots of research, analyses, education and service within the potato sector.

- Intensive quality system with strict inspections in accordance with the strictest standards (food safety, environment, technological quality, sustainability, traceability, etc.).

- Central location and diverse transport possibilities guarantee quick service and flawless delivery.

- European ‘yellow flesh’ potatoes are the best choice for fries.

- Belgian chip stand culture is popular worldwide.

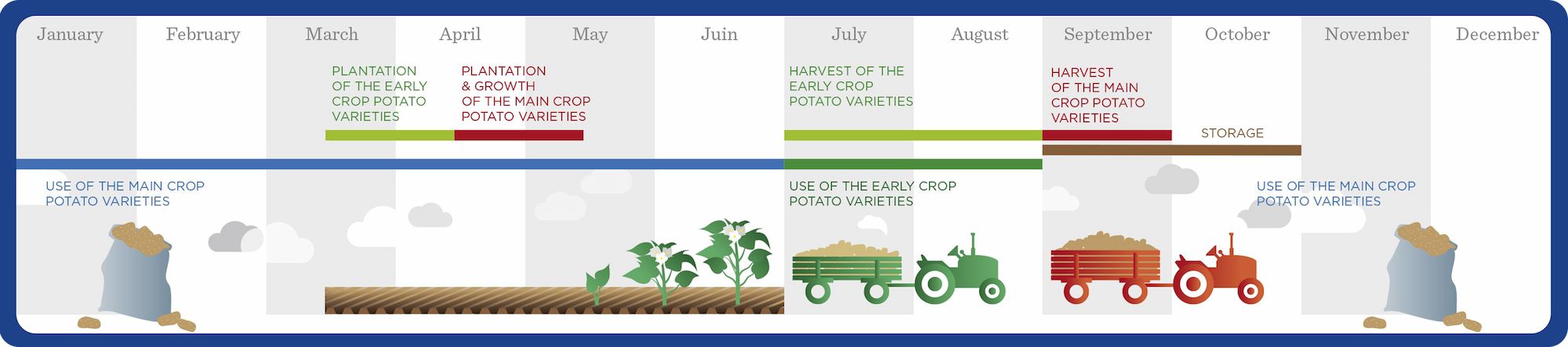

Potato Cycle

This graph represents the standard cycle of the potato. Each year, this graph may change depending on the weather conditions.

From a standard cycle, the season of plantation starts from mid-March and ends mid-May. We start with the early crop potato varieties to finish with the main crop potato varieties. Regarding the harvest season, it happens during the summer for the early crop while the harvest of the main crop happens in September. Once the harvest season has started, the storage phase begins and comes to an end around end-October.

From potato field to finished product, Mydibel knows how to tackle things.

Our know-how and strict quality control during every phase of the production process guarantees the perfect processing of potatoes into top-class products that are enjoyed by the food service, industry and retailers.

From potatoes to finished products

- Our farmers bring top-quality potatoes to the Mydibel potato reception.

- After a thorough quality control, the potatoes are calibrated, sorted, washed and transported to the production line via a water bridge.

- After peeling, cutting and pre-frying, the potato products are chilled and frozen to -18 °C/-0.40 °F.

- Packaging, placing on pallets and storage in the freezer warehouse occurs automatically.

- The logistic centre with 8 loading docks and fully automated freezer warehouse with a capacity of 31,000 pallets guarantees smooth order processing, accurate stock management and fast loading.

- The waste products are turned into green energy on site.

- Your favourite Mydibel product is coming to you!

An important aspect in Mydibel is to communicate openly and directly between each other. That's why we collaborate closely with our farmers. The purpose is to support and advice them throughout the potato growing process which enable us to have the best quality for our potato.

Our main goal is to build a long-term relationship with our collaborators.

This harvest of 700,000 T of potatoes requires 16,000 hectares of land, which represents a total of 26,500 football fields.